In the intricate landscape of the Indian Defence and Space sector, Pinaka stands as a beacon of excellence, offering a unique blend of capabilities that extends far beyond conventional boundaries.

This section takes an in-depth exploration of Zetwerk-Pinaka’s extensive Aerospace and Defense capabilities, highlighting its commitment to delivering extremely reliable, end-to-end solutions that redefine the industry.

Zetwerk-Pinaka proudly identifies itself as a “one-stop shop” offering a spectrum of products and solutions across the segment.” This ethos is reflected in its full-spectrum offerings that cover diverse needs within the Defence and Space sector.

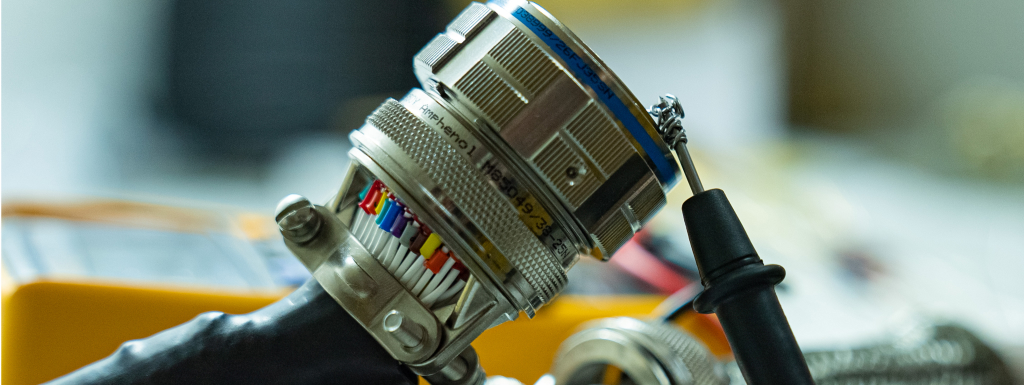

Zetwerk-Pinaka excels in integrating systems and sub-systems utilized in Defence and Aerospace platforms.

Zetwerk-Pinaka has developed an indigenized system for missile platform, extending GTE operability and transmission drives using innovative tech, and in-country support.

Zetwerk-Pinaka’s global supply chain solutions bring strategic sourcing to your doorstep, enabling a just-in-time strategy and localized support for our customers.

Zetwerk-Pinaka excels in integrating systems and sub-systems utilized in Defence and Aerospace platforms.

Zetwerk-Pinaka has developed an indigenized system for missile platform, extending GTE operability and transmission drives using innovative tech, and in-country support.

Zetwerk-Pinaka’s global supply chain solutions bring strategic sourcing to your doorstep, enabling a just-in-time strategy and localized support for our customers.

Zetwerk-Pinaka’s Capabilities: Revolutionizing Aerospace and Defense Technologies

Zetwerk-Pinaka’s manufacturing capabilities are a testament to its dedication to producing high-quality products with precision and efficiency.

High-pressure die casting for precision manufactured parts for consistent quality in complex components and production of durable and intricately designed parts.

Production of metal components using iron-based and non-iron alloys, catering to diverse defense applications.

Shaping metal through compressive forces, enhancing material strength, and producing robust components.

Creating versatile and lightweight profiles used across our range of products and applications.

Combines the design flexibility of plastic injection molding with the durability of metal, for the production of complex and precise metal parts.

Shaping components for high-quality components to precise specifications for exceptional performance.

Pressing, molding, or bending materials to create precise shapes and structures, facilitating the production of a wide range of components.

Shaping and forming thin metal sheets through cutting, bending, and assembling, enabling efficient manufacturing of components.

Injecting molten material for the mass production of complex and detailed components.

Cutting, bending, and assembling metal for the production of customized and durable metal products.

Quality raw materials for appearance enhancement, increased corrosion resistance, and conductivity.

World-class paints and processes for protection, enhance the appearance, durability, and corrosion resistance of surfaces.

High-pressure die casting for precision manufactured parts for consistent quality in complex components and production of durable and intricately designed parts.

Production of metal components using iron-based and non-iron alloys, catering to diverse defense applications.

Shaping metal through compressive forces, enhancing material strength, and producing robust components.

Creating versatile and lightweight profiles used across our range of products and applications.

Combines the design flexibility of plastic injection molding with the durability of metal, for the production of complex and precise metal parts.

Shaping components for high-quality components to precise specifications for exceptional performance.

Pressing, molding, or bending materials to create precise shapes and structures, facilitating the production of a wide range of components.

Shaping and forming thin metal sheets through cutting, bending, and assembling, enabling efficient manufacturing of components.

Injecting molten material for the mass production of complex and detailed components.

Cutting, bending, and assembling metal for the production of customized and durable metal products.

Quality raw materials for appearance enhancement, increased corrosion resistance, and conductivity.

World-class paints and processes for protection, enhance the appearance, durability, and corrosion resistance of surfaces.

Zetwerk-Pinaka’s solutions and services showcase a holistic approach that goes beyond mere product delivery with our turnkey, end-to-end offering that encompasses multiple components and subsystems.

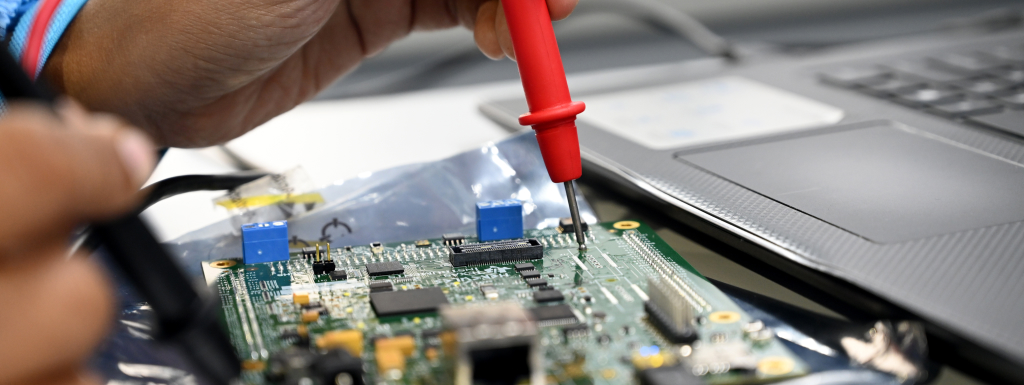

The DFCC-ADC software revolutionizes ADA’s Light Combat Aircraft with real-time data acquisition and analysis, ensuring reliable results for swift decision-making and optimized aircraft performance. Unlock enhanced efficiency, valuable insights, and operational optimization with Zetwerk-Pinaka’s groundbreaking innovation.

Our innovative Alignment System utilizes state-of-the-art RF tech, remote control, swift deployment, and reliable in-country support for uninterrupted performance.

SW Services, Doc Services with IEEE-12207 | MIL-498 | DO-178B | DO-254

Zetwerk-Pinaka excels in MRO, showcasing expertise in Airborne Rotables to Gas Turbine Engines, and APUs, with automated diagnosis, quick turnaround, and a commitment to excellence.

The indigenous TGT Amplifier addresses legacy failures, and enhances performance, extending operational life until the mid-2030s in the Rolls-Royce Adour MK804/MK811 Engines for IAF’s SEPECAT Jaguar fleet.

The DFCC-ADC software revolutionizes ADA’s Light Combat Aircraft with real-time data acquisition and analysis, ensuring reliable results for swift decision-making and optimized aircraft performance. Unlock enhanced efficiency, valuable insights, and operational optimization with Zetwerk-Pinaka’s groundbreaking innovation.

Our innovative Alignment System utilizes state-of-the-art RF tech, remote control, swift deployment, and reliable in-country support for uninterrupted performance.

SW Services, Doc Services with IEEE-12207 | MIL-498 | DO-178B | DO-254

Zetwerk-Pinaka excels in MRO, showcasing expertise in Airborne Rotables to Gas Turbine Engines, and APUs, with automated diagnosis, quick turnaround, and a commitment to excellence.

The indigenous TGT Amplifier addresses legacy failures, and enhances performance, extending operational life until the mid-2030s in the Rolls-Royce Adour MK804/MK811 Engines for IAF’s SEPECAT Jaguar fleet.

Zetwerk-Pinaka’s strengths and the value it brings to its customers are integral to its success.

AS9100D, CMMI-3, ISO9001, CEMILAC, and DGAQA Certifications with strong ecosystem partnerships with reputed industry players

ZETWERK’s advanced project management techniques include a combination of custom-made technology and the right tools to provide real-time project status at every stage, fully supported by embedded teams assisting in Purchase Orders, Tool Design, DFM, FAIR Approval, Inventory Management, and Delivery.

Zetwerk-Pinaka is among the fastest-growing companies in India and is backed by some of

the leading technology investors.

Zetwerk-Pinaka has developed in-house technological capabilities that we deploy in tandem with industry-standard software to deliver as per customer specifications.

Pinaka Aerospace Solutions Pvt. Ltd., seeks the continual improvement of our quality management system, business processes, and delivery models to provide our customers innovative products and solutions that fully satisfy their requirements first time and every time.

We deliver all projects undertaken on time and in full with complete transparency at every stage.

Founders and Senior Executive team with extensive experience with the DRDO, IAF, Defense PSUs, and Global IT Majors. The engineering team brings a unique combination of domain specialists, designers, embedded and application hardware and software engineers, and QA engineers.

AS9100D, CMMI-3, ISO9001, CEMILAC, and DGAQA Certifications with strong ecosystem partnerships with reputed industry players

ZETWERK’s advanced project management techniques include a combination of custom-made technology and the right tools to provide real-time project status at every stage, fully supported by embedded teams assisting in Purchase Orders, Tool Design, DFM, FAIR Approval, Inventory Management, and Delivery.

Zetwerk-Pinaka is among the fastest-growing companies in India and is backed by some of

the leading technology investors.

Zetwerk-Pinaka has developed in-house technological capabilities that we deploy in tandem with industry-standard software to deliver as per customer specifications.

Pinaka Aerospace Solutions Pvt. Ltd., seeks the continual improvement of our quality management system, business processes, and delivery models to provide our customers innovative products and solutions that fully satisfy their requirements first time and every time.

We deliver all projects undertaken on time and in full with complete transparency at every stage.

Founders and Senior Executive team with extensive experience with the DRDO, IAF, Defense PSUs, and Global IT Majors. The engineering team brings a unique combination of domain specialists, designers, embedded and application hardware and software engineers, and QA engineers.

Zetwerk-Pinaka’s diverse portfolio and collaborative initiatives are instrumental in shaping the future of the Defence and Space industry.

Zetwerk-Pinaka has pioneered an indigenous Transmission Control System for Military BMP Vehicles, introducing automated torque and speed management with up to 4 forward and two reverse gears, streamlining performance in a new era of efficiency.

Zetwerk-Pinaka’s G-Meter is at the forefront of monitoring capabilities across various avionics subsystems. The device records up to 16G impact events, capturing vital data for analysis and maintenance. It meticulously records the direction, amplitude, and max peak events in individual X, Y, and Z axes.

Zetwerk-Pinaka has pioneered an indigenous Transmission Control System for Military BMP Vehicles, introducing automated torque and speed management with up to 4 forward and two reverse gears, streamlining performance in a new era of efficiency.

Zetwerk-Pinaka’s G-Meter is at the forefront of monitoring capabilities across various avionics subsystems. The device records up to 16G impact events, capturing vital data for analysis and maintenance. It meticulously records the direction, amplitude, and max peak events in individual X, Y, and Z axes.

Pinaka Aerospace Solutions P. Ltd, a Zetwerk company, is housed in a cutting-edge Aerospace and Defense facility spanning 90,000 sq. ft. in Bengaluru. The facility is equipped with state-of-the-art infrastructure and houses over 10 test systems, including Thermal Shock and Vibration machines. We are capable of a three-week turnaround time, significantly reducing repair durations. Zetwerk-Pinaka’s track record includes supplying systems for combat aircraft, delivering mission-critical LRUs for the Indian Air Force, and deploying Gas Turbine Engines MRO for the IAF and Indian Army.

Zetwerk-Pinaka offers a comprehensive range of services, including system integration, indigenization, and supply chain solutions. The product lineup features advanced offerings like the DFCC-ADC Data Acquisition Simulator and Missile Alignment System, and our manufacturing capabilities cover high-pressure die casting, forging, precision machining, and more. We provide turnkey solutions encompassing data acquisition, mobile stations, maintenance, and indigenization.

Certified with AS9100D, CMMI-3, ISO9001, CEMILAC, and DGAQA, Zetwerk-Pinaka places a strong emphasis on processes, financial stability, technology, quality, and timeliness. We are managed by personnel who have been leaders at DRDO, IAF, Defense PSUs, and Global IT Majors. We collaborate on diverse, high-impact projects that shape the Defence and Space industry. Zetwerk-Pinaka combines technical prowess, domain expertise, and robust infrastructure to contribute significantly to the Defense and Space sector, ensuring the timely delivery of high-quality products to defense establishments.

Ready to maximize manufacturing?