Challenges and Solutions: Developing Side-Step Assembly for an Electric Two-Wheeler

A Bengaluru-based electric two-wheeler manufacturer, faced a significant challenge in developing a side-step assembly for their new vehicle model within a tight twelve-week timeframe. The precision manufacturing sector’s intricate nature demanded effective management of multiple commodities, necessitating a robust supply chain. Challenges included identifying suitable supply chain partners, setting up seamless assembly lines, maintaining stringent quality standards across diverse components, and coordinating precise delivery plans to meet the demanding timeline.

Challenges

The company faced the daunting task of developing a side-step assembly for their new vehicle model within a tight twelve-week timeframe. The intricate nature of the precision manufacturing sector demanded the management of multiple commodities, necessitating a robust supply chain. The challenges included identifying suitable supply chain partners, setting up seamless assembly lines, maintaining stringent quality standards across diverse components, and coordinating precise delivery plans to meet the demanding timeline.

Opportunities

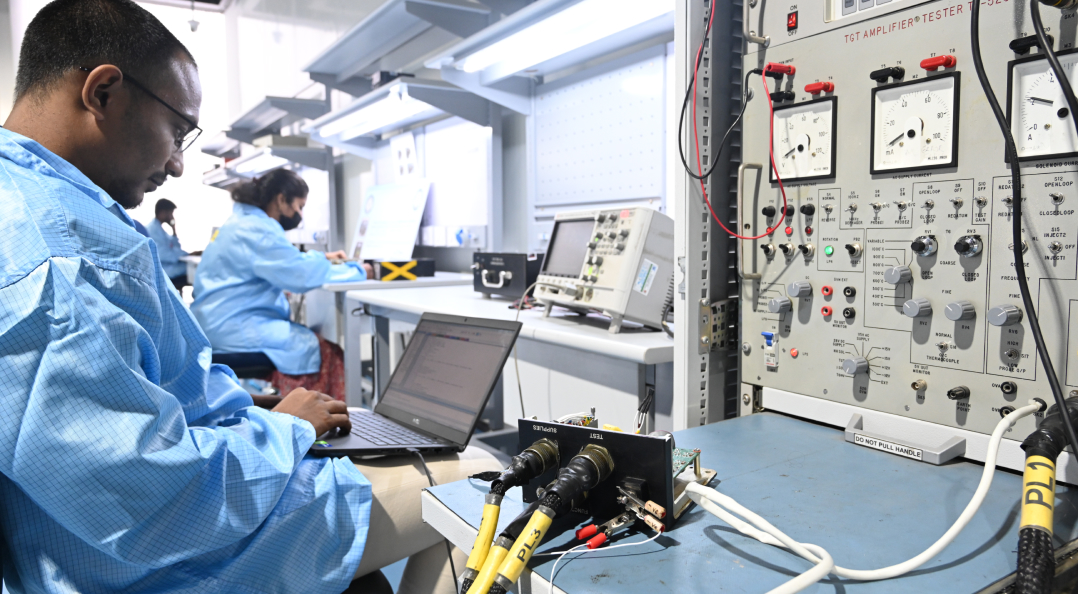

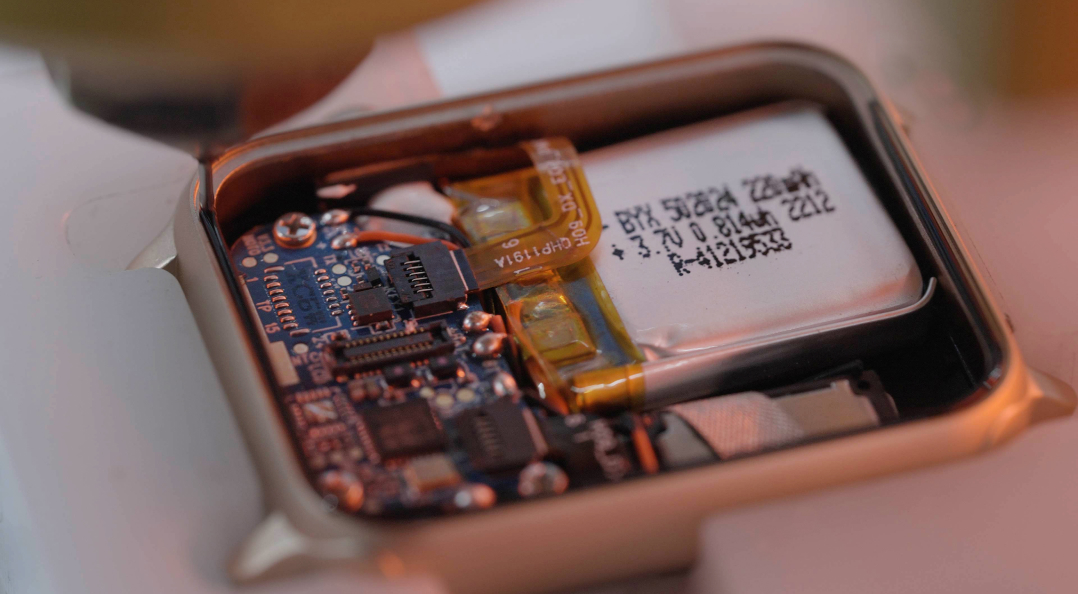

Amidst these challenges, ZETWERK seized the opportunity to streamline the supply chain by leveraging its network of suppliers for end-to-end production. Advanced assembly line setup practices were implemented, incorporating best-in-class standards and efficiency measures. ZETWERK also capitalized on the opportunity to ensure quality assurance, define standards, implement AQL for part qualification, and secure quality tooling and approval. Efficient delivery planning became an opportunity to minimize gaps in the supply chain, mitigating risks and ensuring smooth inventory management.

Impact

ZETWERK’s strategic interventions yielded significant impact across various facets of the project. The tooling and part approval process was completed in just seven weeks, cutting down the lead time by four weeks and ensuring timely delivery. Quality control excellence was demonstrated through zero defects, best-in-class standards, and AQL sampling for aesthetic part qualification. The assembly line operated seamlessly, thanks to the implementation of Poka-yoke practices, enhancing productivity and minimizing errors. Robust delivery planning resulted in zero gaps, effectively managing demand fluctuations and ensuring a steady supply chain. Ultimately, ZETWERK’s comprehensive approach not only addressed the challenges presented by the project but also optimized processes, contributing to the successful and timely launch of the new electric two-wheeler model.